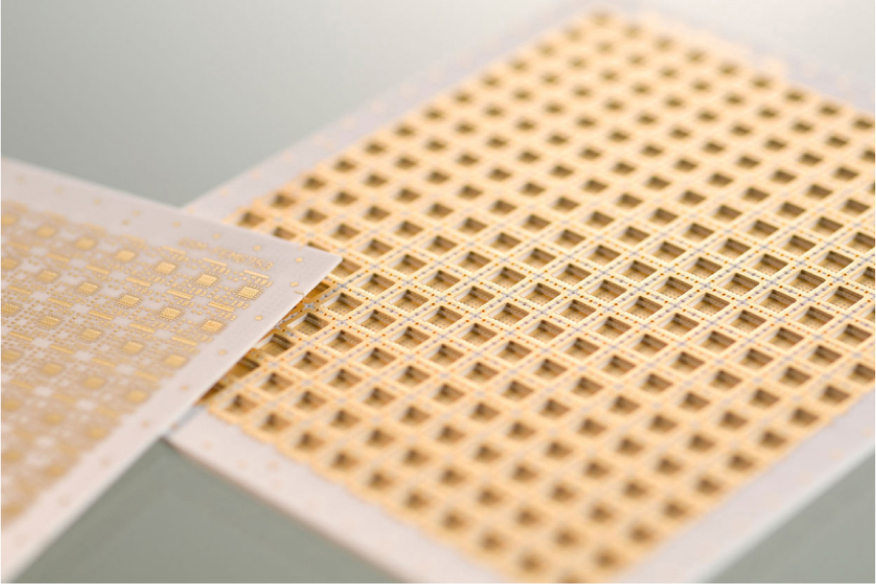

HTCC Multilayer Substrates

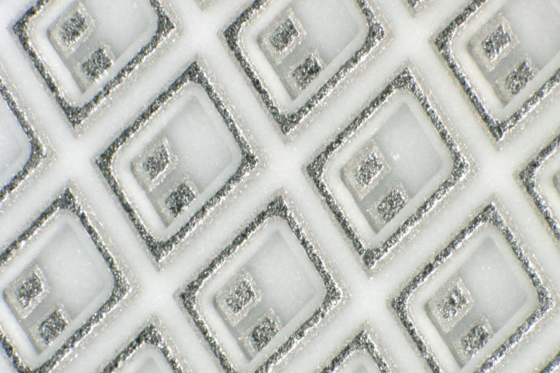

The NIKKO HTCC substrates are co-fired multilayer circuit substrates made by Pt conductors and Alumina ceramics and are also available in cavity structures.

Features

- The new NIKKO HTCC substrates with platinum conductors are extremely chemically stable, therefore do not oxidate easily, and can be used in various high-temperature environments.

- Compatible with SDGs and low cost as it does not require plating for surface treatment.

- Bio-friendly material used in a wide range of medical applications.

- Offers the catalytic effect of Pt.

- High strength due to the higher content of alumina compared to typical HTCC material along with high thermal conductivity and low dielectric loss of ceramics.

- High dimensional tolerance (±0.3%)

Material Characteristics

| ITEM | UNIT | HTCC NHP-96 |

|---|---|---|

| DIELECTRIC CONSTANT @1MHz/10GHZ | ― | 9.3/9.0 |

| DIELECTRIC LOSS @1MHz/10GHz | ×10-4 | 2/4 |

| SPECIFIC GRAVITY | g/cm3 | 3.75 |

| THERMIAL CONDUCTIVITY | W/(m・K) | 23 |

| THERMAL EXPANSION COEFFICIENT | ppm/℃ | 6.8 |

| BENDING STRENGTH | MPa | 450 |

| MATERIAL | ― | ALUMINA 96% |

| GREEINSHEET THICKNESS | mm | 0.05~1.0 |

| CONDUCTOR | ― | Pt |

| SURFACE CONDUCTOR | ― | Pt |

| DIMENSIONAL TOLERANCE | % | ±0.3 |

Design Guidelines

| CATEGORY | DRAWING POSITION | ITEM | DESIGN RULES |

|---|---|---|---|

| SUBSTRATE | ― | DIMENSIONS | MAX: 120x 110 |

| ― | THICKNESS | MIN: 0.2mm | |

| ― | CAVITY | AVAILABLE | |

| ― | SHIPPING PACKAGE | SUBSTARTE: SEPARATE DEVICES | |

| ― | SINGULATION | G CUT, LASER, DICING | |

| ― | PATTERN DISTANCE TOLERANCE | MIN:±0.3% | |

| DIELECTRIC | ― | LAYER THICKNESS | 0.07~1.0mm |

| ― | # OF LAYERS | 20 LAYER CIRCUITS AVAILABLE | |

| PATTERN (CO-FIRED) | A | VIA DIMETER | 0.05~0.2mm |

| B | VIA PITCH | MIN:0.25mm | |

| C | INTERNAL VIA PAD DIAMETER | STANDARD: VA DIAMETER + 0.05mmΦ | |

| D | LINE WIDTH | MIN:0.05±0.02(TARGET 0.01)mm | |

| E | LINE SPACE DISTANCE | MIN:0.05±0.02(TARGET 0.01)mm | |

| F | LINE/VIA PAD DISTANCE | MIN:0.1mm | |

| G | VIA EDGE/CAVITY EDGE DISTANCE | MIN:0.2mm | |

| H | VIA EDGE/SUBSTRATE EDGE DISTANCE | MIN:0.2mm | |

| J | PATTERN/SUBSTRATE EDGE DISTANCE | MIN:0.15mm | |

| K | VIA PAD/BULK PATTERN DISTANCE | MIN:0.2mm | |

| L | HOLE DIAMETER | MIN:0.55mm | |

| M | BULK PATTERN/SUBTRATE EDGE DISTANCEMIN:0.15mm | MIN:0.15mm | |

| OVERCOAT (CO-FIRED) | N | OVERLAP WITH CONDUCTOR | MIN:0.075mm |

| P | CLEARANCE FROM VIA | MIN:0.1mm | |

| Q | OVERLAP WITH CONDUCTOR | MIN:0.1mm | |

| R | CLEARANCE FROM CONDUCTOR | MIN:0.1mm | |

| S | PARTIAL OVERLAP WITH VIA | NOT AVAILABLE | |

| T | CLEARANCE FROM SUBSTRATE EDGE | MIN:ZERO | |

| U | PATTERN WIDTH | MIN:0.1mm |

Catalog Download

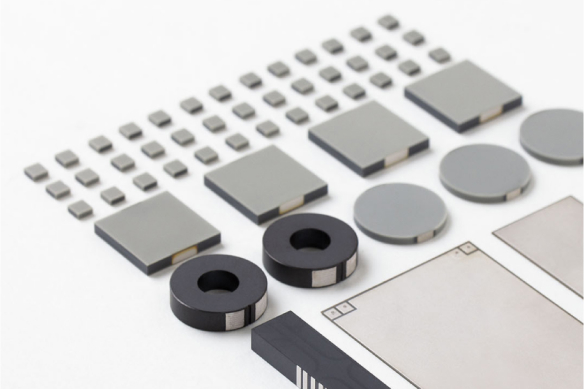

Product Use Case

- Plasma (Ozone) generators

- Medical applications

- Small device packages – sensor packages