High Strength Alumina Substrates(NA-96F1)

NIKKO’s high-strength Alumina substrates offer high strength, high toughness, and high thermal shock resistance. Their excellent thermal shock properties are ideal for applications such as heater substrates and power modules.

Features

NIKKO’s high-strength substrates show significant improvement in the thermal shock resistance compared to the standard Alumina substrates. The bending strength after a thermal shock test is over 2x compared to the standard Alumina substrate. Ideal for applications that require high thermal shock resistance. Various dimensions and thicknesses are available.

Material Characteristics

| ITEM | UNIT | TEST CONDITIONS | 96% ALUMINA | HIGH STRENGTH | ALUMINA -ZIRCONIA | |

|---|---|---|---|---|---|---|

| NA-96 | NA-96F1 | NA-Z | ||||

| MATERIAL | ― | ― | 96%Al2O3 | 96%Al2O3 | Al2O3-ZrO2 | |

| COLOR | ― | ― | WHITE | WHITE | WHITE | |

| DENSITY | g/cm3 | ― | 3.7 | 3.7 | 4.1 | |

| WATER ABSORPTION | % | ― | 0 | 0 | 0 | |

| MECHANICAL PROPERTIES | 3 POINT BENDING STRENGTH | MPa | ― | 400 | 450 | 600 |

| THERMAL PROPERTIES | THERMAL EXPANSION COEFFICIENT | 10-6/℃ | RT~400℃ | 6.8 | 6.8 | 7 |

| RT~800℃ | 7.8 | 7.8 | 8.1 | |||

| THERMAL CONDUCTIVITY | W/(m・K) | 20℃ | 23 | 23 | 21 | |

| ELECTRICAL PROPERTIES | DIELECTRIC CONSTANT | ― | 1MHz | 9.2 | 9.3 | 11.3 |

| LOSS TANGENT | 10-4 | 1MHz | 10 | 10 | 12 | |

| ELECTRICAL RESISTIVITY | Ω・cm | 25℃ | >1014 | 5×1015 | >1014 | |

| 300℃ | 1012 | 2×1012 | 1011 | |||

| 500℃ | 1010 | 2×109 | 109 | |||

| DIELECTRIC STRENGTH | kV/mm | ― | >20 | >20 | >20 | |

Design Guidelines

| ITEM | UNIT | LASER PROCESSED | CUSTOM |

|---|---|---|---|

| DIMENSIONS | mm | ~150×300 | ~300×300 |

| THICKNESS | mm | 0.635, 0.8, 1.0 | 0.32~1.0 |

| VIA DIAMETER | mm | Φ0.3~ | Φ0.15 |

Catalog Download

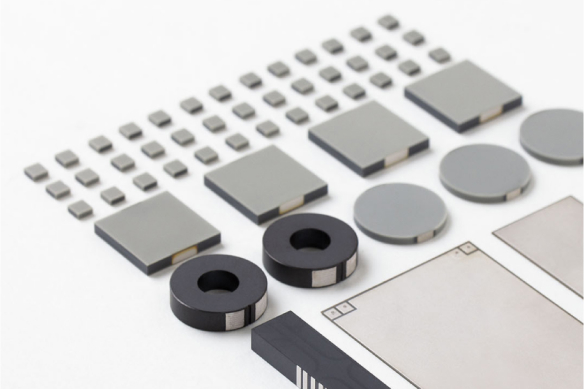

Product Use Cases

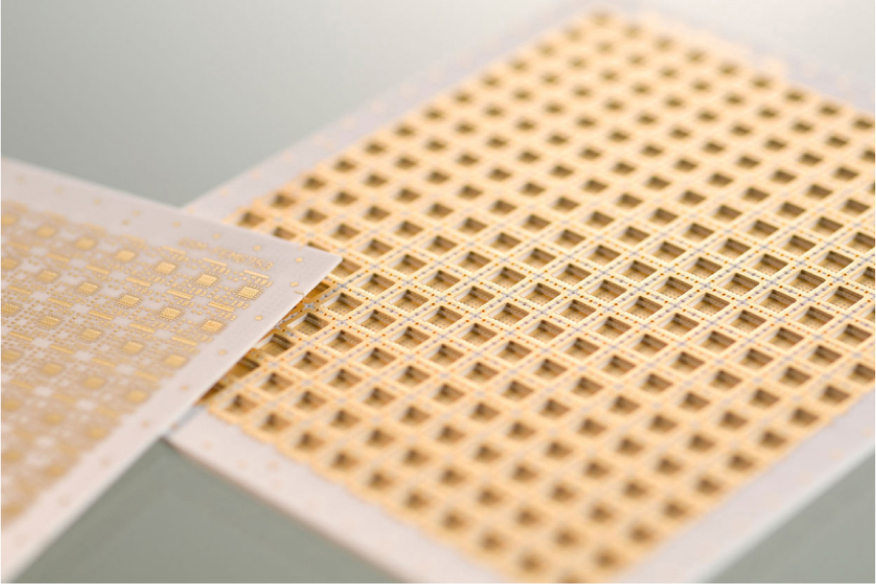

- Laser processed substrates

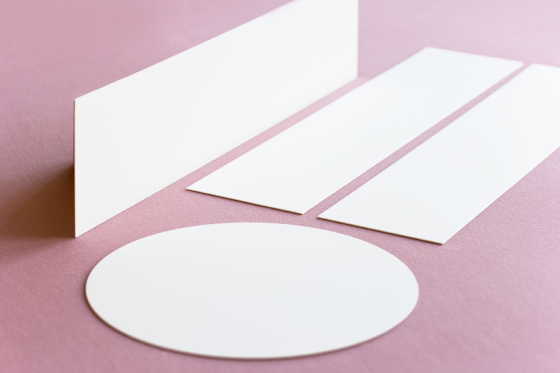

- Polished substrates

- Thick film circuit substrates

- Glazed substrates