96% Alumina(NA-96)

96% Alumina substrates are standard typical ceramic substrates. The stability of physical and chemical properties under high temperatures allows for high operating temperatures and high environmental temperatures, which are ideal for products that require high reliability.

Features

96% Alumina substrates offer high electrical insulation and combined with the stability of physical and chemical properties under high temperatures, are ideal for applications such as Power devices, Automotive, and heater substrates. Substrates offer excellent flatness with minimum camber and surface unevenness.

Material Characteristics

| ITEM | UNIT | TEST CONDITIONS | 96% ALUMINA | HIGH STRENGTH | ALUMINA -ZIRCONIA | |

|---|---|---|---|---|---|---|

| NA-96 | NA-96F1 | NA-Z | ||||

| MATERIAL | ― | ― | 96%Al2O3 | 96%Al2O3 | Al2O3-ZrO2 | |

| COLOR | ― | ― | WHITE | WHITE | WHITE | |

| DENSITY | g/cm3 | ― | 3.7 | 3.7 | 4.1 | |

| WATER ABSORPTION | % | ― | 0 | 0 | 0 | |

| MECHANICAL PROPERTIES | 3 POINT BENDING STRENGTH | MPa | ― | 400 | 450 | 600 |

| THERMAL PROPERTIES | THERMAL EXPANSION COEFFICIENT | 10-6/℃ | RT~400℃ | 6.8 | 6.8 | 7 |

| RT~800℃ | 7.8 | 7.8 | 8.1 | |||

| THERMAL CONDUCTIVITY | W/(m・K) | 20℃ | 23 | 23 | 21 | |

| ELECTRICAL PROPERTIES | DIELECTRIC CONSTANT | ― | 1MHz | 9.2 | 9.3 | 11.3 |

| LOSS TANGENT | 10-4 | 1MHz | 10 | 10 | 12 | |

| ELECTRICAL RESISTIVITY | Ω・cm | 25℃ | >1014 | 5×1015 | >1014 | |

| 300℃ | 1012 | 2×1012 | 1011 | |||

| 500℃ | 1010 | 2×109 | 109 | |||

| DIELECTRIC STRENGTH | kV/mm | ― | >20 | >20 | >20 | |

Design Guidelines

| ITEM | UNIT | DIE PROCESSED | LASER PROCESSED | CUSTOM |

|---|---|---|---|---|

| DIMENSIONS | mm | 50×50~130×120 | ~150×300 | ~300×300 |

| THICKNESS | mm | 0.635, 0.8, 1.0 | 0.635, 0.8, 1.0 | 0.32~1.6 |

| VIA DIAMETER | mm | Φ0.3~ | Φ0.3~ | Φ0.15~ |

Catalog Download

Product Use Cases

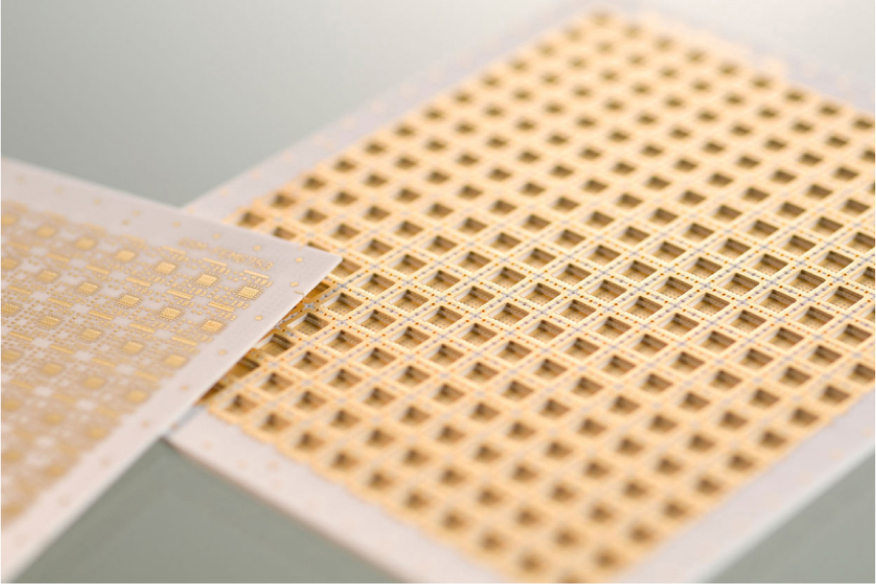

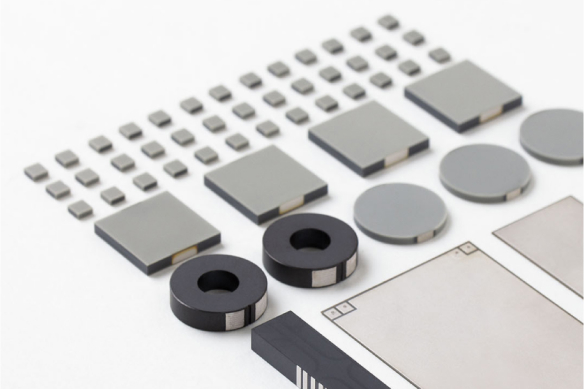

- Laser processed substrates

- Polished substrates

- Thick film circuit substrates

- Glazed substrates